New Technology Building Materials

a novel electrochemical process sequesters carbon by means of a flexible building product.

Avoiding dangerous climate change may require removing skin tightening and straight from the atmosphere.

An innovative new method for taking skin tightening and directly from the atmosphere and converting it to oxygen and nanoscale fibers made from carbon can lead to a relatively inexpensive method to make a very important building material—and may even serve as a weapon against climate modification.

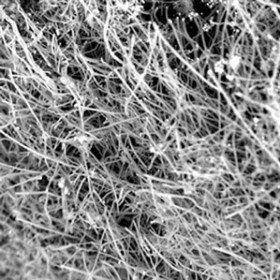

The fibers within microscope image are constructed of carbon, produced via a brand new technique that also removes skin tightening and from environment.

The fibers within microscope image are constructed of carbon, produced via a brand new technique that also removes skin tightening and from environment.

Carbon materials tend to be progressively used as an architectural material from the aerospace, automotive, alongside companies, which appreciate its strength and light weight. The useful qualities of carbon fibers, which also consist of electric conductivity, are enhanced during the nanoscale, states Stuart Licht, a professor of biochemistry at George Washington University. The problem is it’s very costly to make carbon fibers, never as nanofibers. Licht says his team’s recently demonstrated technology, which both captures the co2 from atmosphere and uses an electrochemical procedure to transform it to carbon nanofibers and oxygen, is much more efficient and possibly a whole lot cheaper than current practices.

Nonetheless it’s more than just an easier, less costly method of making a high-value item. It’s also a “means of saving and sequestering carbon dioxide in a useful manner, a well balanced way, plus in a tight fashion, ” says Licht. He explains that when the process is run on renewable energy, the result is a net removal of skin tightening and from the atmosphere. In a current demonstration, their team utilized a unique concentrated solar power system, making usage of infrared sunlight along with visible light to build the large quantity of temperature necessary to run the specified reaction.

The procedure requires molten lithium carbonate, with another mixture, lithium oxide, dissolved with it. The lithium oxide combines with co2 in the air, forming much more lithium carbonate. Whenever voltage is used across two electrodes immersed inside molten carbonate, the ensuing reaction produces air, carbon (which deposits on a single of electrodes), and lithium oxide, which is often accustomed capture more co2 and commence the process once more.

The researchers demonstrated the capacity to make multiple various nanofiber forms and diameters by adjusting particular development conditions, including the quantity of present used at specific points of the time together with structure of the various ingredients utilized in the procedure. In addition they showed they are able to make really uniform materials. Licht states the components underlying the formation of the fibers still should be better understood, and he’s confident the team could keep developing more control of the character associated with the fibers it creates.

Are you aware that technology’s emissions-cutting potential, the scientists are positive. They calculate that provided a place not as much as ten percent of the size of the Sahara Desert, the method could pull adequate carbon-dioxide to produce global atmospheric levels return to preindustrial amounts within decade, although we keep emitting the greenhouse gas at increased rate during that period.

Of course, this will need a huge rise in demand for carbon nanofibers. Licht believes the material’s properties, particularly the undeniable fact that it really is therefore lightweight and in addition very good, will spur higher and better usage given that cost comes down, in which he thinks his brand new procedure can help with that. Imagine that carbon fibre composites eventually replace metal, aluminum, as well as concrete as a building material, he states. “At that time, there may be enough use of this so it’s actually acting as a substantial repository of carbon.”