PCC Construction

Rigid sidewalks are named because the pavement framework deflects little under running due to the high modulus of elasticity of these area course. A rigid pavement structure is usually consists of a PCC area course constructed on top of either (1) the subgrade or (2) an underlying base program. Because of its relative rigidity, the pavement structure directs lots over a broad location with one, or at most of the two, structural layers (see Figure 1).

Rigid sidewalks are named because the pavement framework deflects little under running due to the high modulus of elasticity of these area course. A rigid pavement structure is usually consists of a PCC area course constructed on top of either (1) the subgrade or (2) an underlying base program. Because of its relative rigidity, the pavement structure directs lots over a broad location with one, or at most of the two, structural layers (see Figure 1).

Architectural Elements

A typical rigid pavement structure (see Figure 2) includes the area course additionally the fundamental base and subbase classes (if utilized). The surface course (made from PCC) could be the stiffest (as calculated by resistant modulus) and offers the majority of power. The underlying levels are instructions of magnitude less rigid but nonetheless make important efforts to pavement energy plus drainage and frost security.

Exterior Course

The top course could be the layer in contact with traffic loads and is made of PCC. It offers traits such as for example rubbing (see Figure 3), smoothness, noise control and drainage. Furthermore, it functions as a waterproofing level to your underlying base, subbase and subgrade. The top course can differ thick it is often between 150 mm (6 inches) (for light loading) and 300 mm (12 ins) (for hefty loads and high traffic). Figure 4 reveals a 300 mm (12 inch) area training course.

Base Program

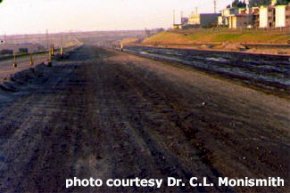

The base training course is instantly under the surface program. It provides (1) extra load circulation, (2) plays a role in drainage and frost weight, (3) uniform support to your pavement and (4) a reliable system for construction gear (ACPA, 2001). Bases in addition help prevent subgrade earth motion considering slab pumping. Base courses are often built out-of:

- Aggregate base. An easy base span of crushed aggregate has-been a standard alternative since the early 1900s and it is nevertheless proper in many situations these days.

- Stabilized aggregate or soil (see Figure 5). Stabilizing agents are accustomed to bind usually free particles to one another, offering power and cohesion. Cement addressed basics (CTBs) are created to just as much as 20 – 25 % associated with the area training course power (FHWA, 1999). But cement treated basics (CTBs) used in the 1950s and very early sixties had a propensity to drop excessive levels of material resulting in panel cracking and deciding.

- Dense-graded HMA. In circumstances where large base stiffness is desired base courses could be built utilizing a dense-graded HMA layer.

- . Using situations in which high base stiffness and exemplary drainage is desired, base classes is constructed using an available graded HMA.

current analysis may show some considerable issues with ATPB usage.

current analysis may show some considerable issues with ATPB usage. - Lean tangible (see Figure 6). Contains less portland cement paste than a normal PCC and it is more powerful than a stabilized aggregate. Slim tangible basics (LCBs) could be developed to around 25 – 50 per cent of this area course power (FHWA, 1999). A lean concrete base functions much like a typical PCC surface training course and for that reason, it needs building joints and will break over time. These bones and splits could trigger reflection breaking in surface training course if they are not carefully coordinated.

Subbase Program

The subbase training course is the percentage of the pavement framework amongst the base program and the subgrade. It works mostly as structural assistance but it may:

- Lessen the intrusion of fines from the subgrade in to the pavement construction.

- Improve drainage.

- Supply a functional system for construction.

The subbase typically is made from lower high quality products compared to base program but much better than the subgrade soils. Appropriate materials tend to be aggregate and quality architectural fill. A subbase program isn't always needed or used.